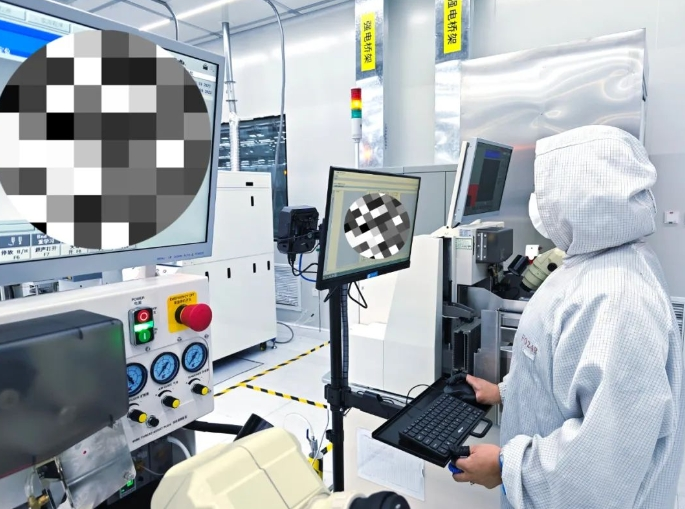

In 2023, the integrated circuit seal and test production line of CETC's 47 institutes will further accelerate the pace of Digital transformation and upgrade to "intelligent manufacturing". Through implementing lean management, carrying out visual data analysis, and promoting Paperless office operations, the flexible production will be improved in quality and efficiency, and the enabling role of Digital transformation will be initially demonstrated.

47 universities are comprehensively promoting the digital construction of production lines. Firstly, we will continue to accelerate the optimization and improvement of the MES system, continuously standardize the process flow and execution of the sealing and testing business unit, further solidify the production management process, and improve management efficiency; Secondly, based on the MES database, the Ministry of Information Technology has launched independent development of data display, statistics, and analysis functions, launched production data dashboards, and achieved transparency in the manufacturing execution process and product quality monitoring; Third, start the production line Paperless office, complete the electronization of the first batch of assembly drawings, process documents, detailed specifications and other drawing documents, configure the production line station terminal, and comprehensively ensure the consistency of the process and drawings; The fourth is to explore the networking and data collection of production line equipment, and to achieve pilot verification and key equipment network testing before the end of the year.

In the process of promoting digital construction, relevant departments overcame difficulties such as management mode adjustment and lack of development experience, and established over 1000 process logic formulas, over 300 process modules, over 200 process flows, nearly 200 product flows, over 200 digital image documents, and 3 solutions, accumulating rich knowledge achievements. In the process of promoting the application, we carried out eight Digital transformation trainings, trained more than 160 people, and covered 100% of production line personnel, achieving good landing results.

(Source/47 institutes)